What is machine vision?

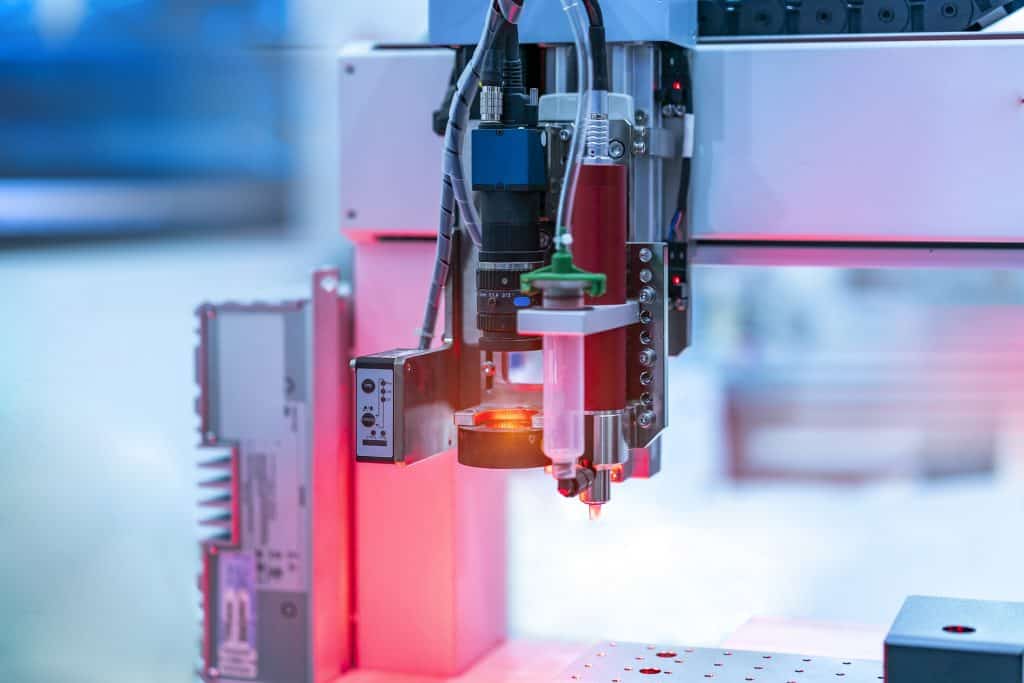

Computer and machine vision systems use sensors to observe and understand the surrounding environment.

Computer vision can be found in a wide variety of technologies, including security features like facial recognition, automated appliances like robotic vacuum cleaners, or self-driving vehicles.

Machine vision refers to the vision systems found in factories, warehouses and logistics operations.

Both computer vision and machine vision ultimately replace the need for human eyesight by using a combination of cameras, sensors, and customized software. This allows the technology to not only “see,” but also interpret visual data to make decisions and act upon those decisions.

What are the benefits of machine vision for manufacturing automation?

A machine vision system is programmed to automatically interact with its surroundings by identifying, inspecting, analyzing, measuring, and sorting parts and products along the assembly line. Machine vision positively impacts the world of manufacturing, warehousing, and logistics in countless ways, ultimately leading to higher quality, reduced waste and an improved bottom line.

There are many benefits to machine vision, including:

Consistency & Accuracy

Machine vision systems are capable of closely inspecting and measuring components to ensure consistent production on the assembly line. Machine vision can identify whether components are aligned and assembled correctly. It can effectively remove defective products from the assembly line, long before products reach the end user. Companies can maintain the highest levels of quality and prevent costly returns and product recalls.

On the compliance side of things, machine vision systems can read text and barcodes to ensure the completion and accuracy of packaging and labels. They can also collect compliance-related data and track & trace components, providing real-time information throughout the assembly line, packaging processes, and shipping.

Efficiency & Waste Reduction

Automation ensures that operations can run continuously, without a hitch. Data analysis can identify frequent sources of error that must be corrected. Algorithms can be adjusted and updated as operating needs change.

Machine vision can quickly detect machine malfunction before a problem gets out of hand, and even predict the upcoming need for maintenance, minimizing assembly line downtime. When errors and defects are caught early in the manufacturing process, machine vision systems can remove defective components from the assembly line so that no further time and materials are wasted on packaging, shipping, returns, etc.

Employee Safety & Utilization

Machine vision systems work more quickly, consistently, and reliably on repetitive tasks than their human counterparts, who may become tired or distracted. Machine vision can circumvent the issue of labor shortages by freeing up the human labor force for more specialized or complex tasks.

Machine vision can prevent errors and injuries that occur because of human fatigue. With machine vision, some errors can be resolved remotely, for safety and convenience. It can even monitor the manufacturing environment for potential safety hazards, alerting those in the area if danger is detected.

How can you incorporate machine vision into your current environment?

Machine vision can have a positive impact on so many aspects of your manufacturing processes. L-Tron’s team of engineers and product experts can help gradually introduce automation and vision solutions into your business. We will work with you as much – or as little- as you need to incorporate machine vision into your operations.

Here are some of the ways we can help you get started:

- Supply an industrial computer system to your exact specifications.

- Custom configure your chassis for video cards, networking, etc.

- Supply and incorporate barcode scanning equipment.

- Write interface code to integrate the system into your backend database.

- Ensure compatibility between your new and existing equipment.

- Modify existing equipment for cabling and interfacing needs.

- Test and demo the vision system equipment on your production line.

Why choose Advantech industrial automation products?

We are proud to partner with Advantech, a leading global supplier of intelligent industrial automation. From embedded automation PCs and data acquisition to remote I/O and human machine interfaces, Advantech’s technology is cutting-edge, reliable, and built to last.

Our premier partnership with Advantech has spanned more than thirty years, due in part to the fact that Advantech’s product line provides us with so much flexibility and dependability in customizing the best hardware for unique applications.

What is the value of working with L-Tron’s Engineering Team?

L-Tron is honored to work alongside companies as they incorporate machine vision for manufacturing automation into their products, test lines, and manufacturing lines. Our engineers become an extension of our clients’ teams. We work through the various stages of development – modifying and customizing industrial equipment for their unique needs. Even when companies have their own engineering teams, they can call upon L-Tron for our expertise, support, and additional time savings. We are proud to help with every aspect of your project, from start to finish.

To discover more about how machine vision systems can improve your current operations, check out these resources: